Introduction

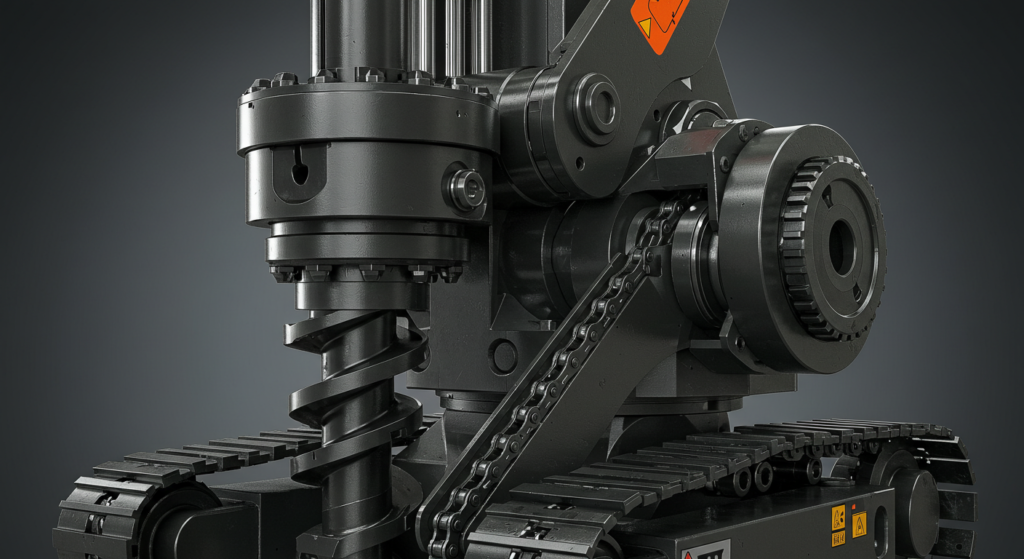

In modern engineering and manufacturing, precision and power go hand in hand. One of the most critical components driving innovation in drilling technology is the spezialbohrgetriebe, or specialized drilling gearbox. Designed to deliver exceptional torque, accuracy, and reliability, a spezialbohrgetriebe plays a vital role in high-performance drilling systems used in sectors such as aerospace, automotive, oil and gas, and renewable energy. Whether it’s boring through composite materials, precision drilling in metal, or high-speed cutting in automated production lines, these specialized gearboxes ensure consistent and efficient motion transfer under the most demanding conditions.

A spezialbohrgetriebe is more than a mechanical component—it’s the heart of any advanced drilling operation. By translating motor energy into controlled, high-torque rotational power, it enables machines to perform with unparalleled precision and endurance. As industries push toward higher standards of efficiency and sustainability, the demand for custom-engineered gearboxes tailored to specific drilling applications continues to grow. This article explores how spezialbohrgetriebe function, their diverse applications, and why they represent a cornerstone of next-generation industrial performance.

The Core Function of a Spezialbohrgetriebe

At its core, a spezialbohrgetriebe is engineered to optimize torque conversion and motion control in drilling systems. These gearboxes are designed to handle extreme loads, maintain precise speed ratios, and minimize vibration—all essential for achieving consistent drilling accuracy. The gearbox serves as an intermediary between the power source and the drill spindle, ensuring that energy is efficiently transmitted with minimal loss. This not only improves the quality of drilling but also reduces wear and tear on both the tool and the machinery.

Moreover, the spezialbohrgetriebe allows operators to fine-tune performance parameters depending on the task. For instance, when drilling through hard alloys or geological formations, the gearbox can adjust output torque for maximum penetration power. In high-speed industrial production, it enables exact speed synchronization across multiple drilling heads, ensuring uniformity and precision. The result is a system that performs flawlessly under pressure—one that translates engineering precision into tangible productivity.

Key Components and Design Principles

A high-quality spezialbohrgetriebe integrates several essential components, each contributing to its durability and precision. These typically include helical or planetary gears, precision bearings, reinforced housing, and advanced lubrication systems. Every part is engineered with tight tolerances to ensure efficient energy transfer and long service life. The gear geometry, in particular, determines torque distribution and noise reduction, allowing the gearbox to operate smoothly even in high-speed environments.

Design principles behind a spezialbohrgetriebe prioritize robustness, adaptability, and energy efficiency. Manufacturers often employ computer-aided simulations to model torque dynamics and predict stress points under real-world conditions. By using high-strength alloys or composite materials, they achieve optimal weight-to-performance ratios. This careful engineering ensures that the gearbox not only meets industry standards but also outperforms conventional designs in reliability and longevity.

Applications Across Industries

The versatility of spezialbohrgetriebe makes them indispensable across a wide range of industries. In the automotive sector, they are used for precision drilling during engine assembly, frame construction, and component fabrication. In aerospace, these specialized gearboxes ensure flawless drilling of lightweight materials such as titanium and carbon fiber composites, where even microscopic deviations can compromise safety.

In the renewable energy field, spezialbohrgetriebe play an increasingly important role in wind turbine manufacturing and geothermal drilling. Their ability to deliver stable torque and withstand extreme operational conditions helps boost productivity while minimizing downtime. Similarly, in oil and gas exploration, these gearboxes ensure continuous performance in harsh environments where temperature, pressure, and vibration can be highly variable.

Advantages of Using Spezialbohrgetriebe

The main advantage of a spezialbohrgetriebe lies in its precision and adaptability. Unlike standard gear systems, these gearboxes can be tailored to specific torque, speed, and load requirements. This customization enables smoother operation, less maintenance, and greater longevity. In addition, their energy-efficient design contributes to cost savings and sustainability goals—critical factors for modern manufacturing enterprises.

Another key benefit is performance consistency. A spezialbohrgetriebe maintains optimal torque even under fluctuating loads, ensuring drilling accuracy across all production cycles. This stability not only enhances product quality but also reduces tool wear and energy consumption. As companies strive for leaner, more efficient production processes, investing in specialized gear systems becomes a strategic advantage that directly impacts operational efficiency.

Customization and Technological Innovation

Modern spezialbohrgetriebe are products of cutting-edge engineering and digital integration. Advanced modeling tools, sensor technology, and IoT-based monitoring systems have revolutionized gearbox design. Today’s units can self-diagnose performance issues, predict maintenance needs, and adjust torque distribution in real time. This makes them not only powerful but also intelligent components within smart manufacturing ecosystems.

Customization plays a central role in the design process. Manufacturers collaborate closely with clients to develop gearboxes optimized for unique drilling conditions, from deep-sea applications to automated production lines. This bespoke engineering ensures that every spezialbohrgetriebe delivers maximum efficiency, minimal downtime, and superior return on investment. Such innovation continues to redefine the limits of mechanical precision and industrial reliability.

Maintenance and Longevity Considerations

Even the most advanced spezialbohrgetriebe requires proper maintenance to ensure consistent performance. Regular inspection of bearings, lubrication systems, and seals helps prevent mechanical failure and extends operational life. Scheduled oil changes and vibration monitoring are standard practices that can significantly reduce downtime. Many manufacturers also offer predictive maintenance solutions that analyze real-time data to forecast potential issues before they arise.

Investing in high-quality maintenance protocols can dramatically enhance the lifespan of a spezialbohrgetriebe. With proper care, these systems can function efficiently for decades, delivering sustained precision and power. As industries embrace predictive maintenance powered by AI and sensor technology, gearbox reliability is reaching new heights—turning traditional mechanical systems into smart, self-optimizing assets.

Future Trends in Spezialbohrgetriebe Technology

The future of spezialbohrgetriebe lies in innovation and integration. As industries move toward Industry 4.0, smart gearboxes equipped with digital twins and data analytics are becoming the norm. These systems enable real-time monitoring, remote diagnostics, and adaptive performance control. Enhanced materials like carbon-reinforced polymers and ceramic coatings are also improving efficiency and reducing environmental impact.

Additionally, sustainability will shape the next generation of spezialbohrgetriebe. Manufacturers are focusing on energy-efficient designs, recyclable materials, and lower carbon footprints throughout production. With advancements in automation and robotics, specialized gear systems will continue to evolve, driving progress in drilling precision, reliability, and cost-effectiveness worldwide.

Conclusion

A spezialbohrgetriebe represents the pinnacle of engineering precision—a component that transforms raw mechanical power into controlled, high-performance motion. From aerospace and automotive to renewable energy, these specialized gearboxes are fundamental to innovation and operational excellence. As industries demand greater accuracy, efficiency, and sustainability, the importance of high-quality, custom-engineered drilling gearboxes will only continue to grow.

Investing in a spezialbohrgetriebe is not just a technical choice—it’s a strategic one. It signifies a commitment to quality, longevity, and forward-thinking engineering. For manufacturers and engineers looking to stay ahead in competitive global markets, adopting advanced gearbox technology is the key to unlocking the next level of productivity and precision.